Transform your sector with our fireproofing solutions

Design a competitive advantage into your products with our technology designed for extreme heat applications.

Share your specific needs with us, and we’ll arrange for samples tailored to your requirements, ready for independent testing.

✓ Custom solution

✓ proven formulations

✓ Many applications

Proven Formulations

In 2013 we purchased and have since updated Maurice Ward’s (the material’s inventor) original formula to today’s material availability and created new ones, while retaining the invention’s remarkable high-temperature resistance characteristic. Here are the four most common formulations, proven effective through both internal and independent customer testing.

Epoxy Resin

Excellent substrate adhesion

High surface hardness

High durability / weather resistance

Casted fireproof hard enclosures, prepreg siding materials.

Silicone

Flexible

Simple application

Fireproof textiles for the military, fire rescue.

Extruded plastics

Flexible

Moldable

Cable sheathing, electrical boxes, interior cabin components, etc.

Acrylic

Water-based

The simplest application

Can be susceptible to weathering

Paint-based system for the construction industry, packaging material.

Thermashield’s dedicated team stands ready to provide recommendations and collaborate on your specific application. In addition, our customers have the opportunity to develop their own formulations using their in-house R&D resources.

Applications

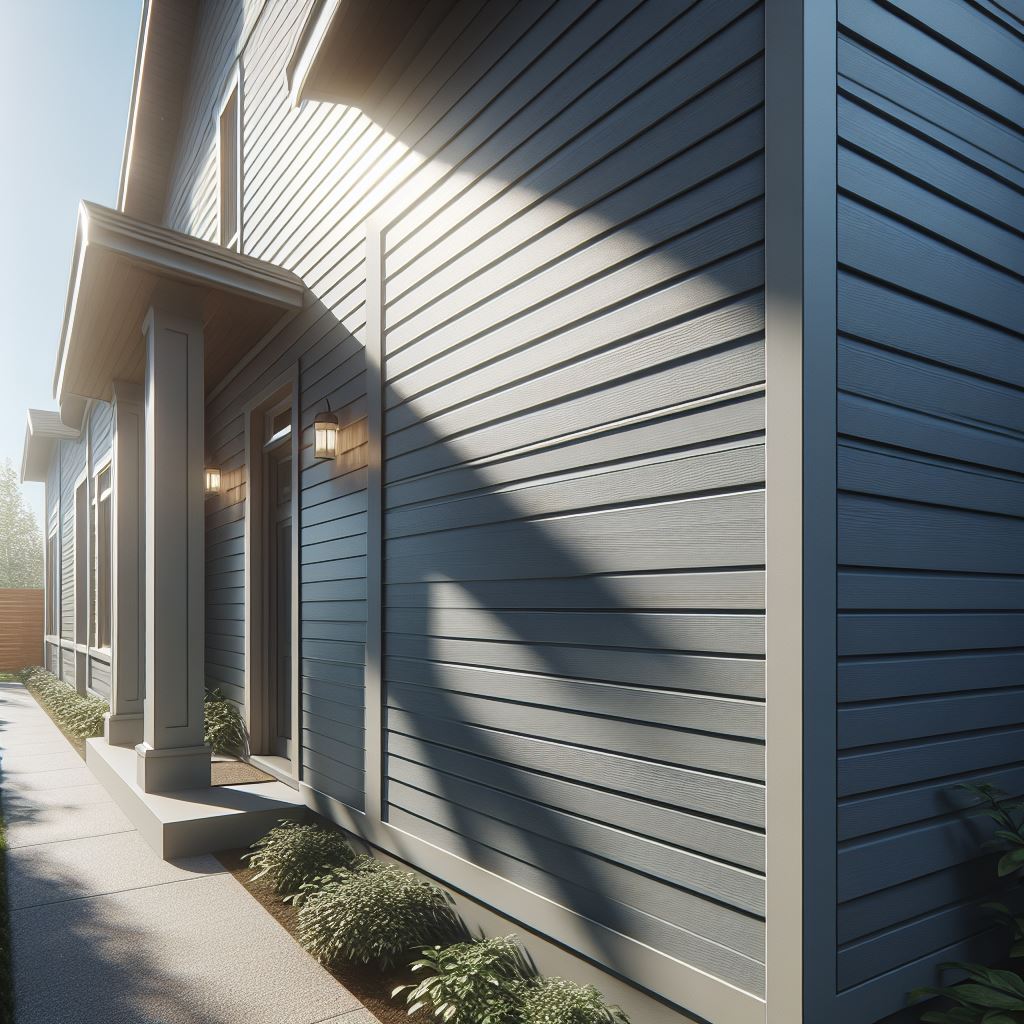

Siding materials

Commercial and Residential exterior siding applications to prevent the spread of fire.

Fireproof textiles

Impregnated fabrics with a silicone-based formulation for fireproofing.

Molded plastics

Extruded plastics with Starlite as an additive to increase fire resistance.

Fireproof cables

Extruded flexible cable sheathing.

Flammable liquid storage

An epoxy-based coating with a solid Starlite % loading to increase fire resistance of the substrate.

Space exploration

Lightweight refurbishable heat shields and high-temperature insulators that are achievable with our technology.

Missile Defense

Several formulations demonstrate remarkable resilience by effectively withstanding intense high-energy laser exposure over extended periods.

Wood products

Multiple interior surfaces can be coated with a chosen Starlite formulation for fireproofing.

Some applications are proven, others are theoretically possible. Thermashield is open to inquiries exploring most types of applications.

Thermashield’s extreme heat resistance technology is reshaping industries from construction to aerospace.

Our proprietary product Starlite can be molded, sprayed, or poured, adapting seamlessly to diverse applications.

Ready to get started?

Simply reach out to our team through the contact us page and share your business name, and potential application.

Can I ask for samples?

Yes, if there is potential to develop a commercial application using Starlite and other factors.

My company wants exclusivity, is it possible?

Yes, depending on the fit. We are currently working with several customers to develop their own applications in select markets.

What is the first step?

After the initial contact we require all interested parties to sign an NDA with us for mutual protection.

What is the cost?

We ask companies interested in samples to cover the costs: raw materials, manufacturing and shipping.

Small exploratory samples are offered free of charge.

How can I invest in Thermashield, LLC?

Please go to the Contact Us page and sign up for the newsletter, using the option to invest. We will reach out to you once we open up company shares for private investment.

Need further assistance?

Unable to find the information you need? Feel free to get in touch. We’re here to help.